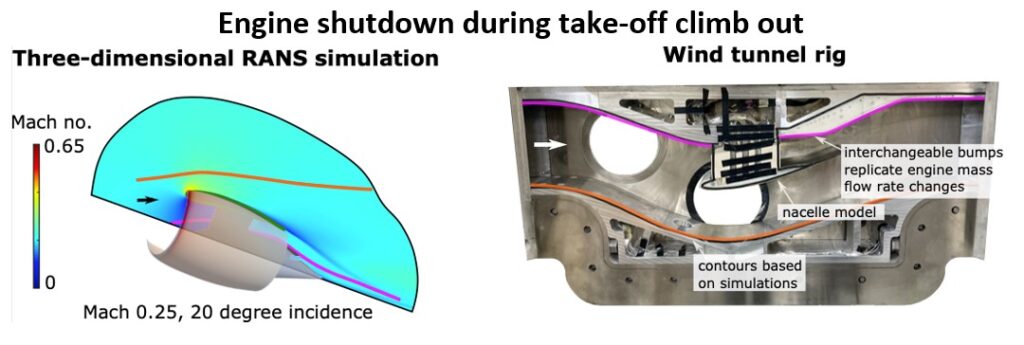

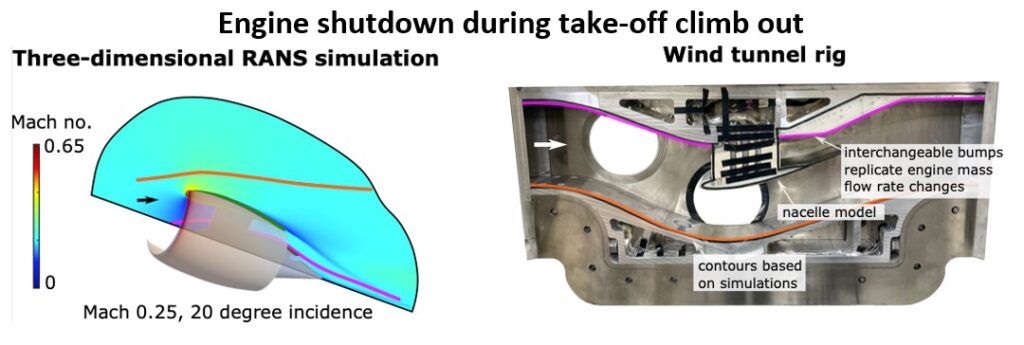

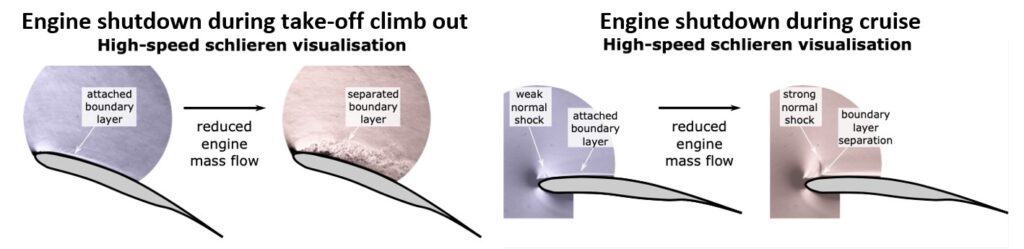

The experimental campaign on external nacelle separation has been completed using a quasi-two-dimensional rig integrated into the transonic wind tunnels at the University of Cambridge. This rig was developed using RANS CFD computations by Cranfield University to faithfully represent the key physical aspects of a compact aero-engine nacelle under windmilling conditions following engine shutdown during both take-off climb out and during cruise. By conducting more than 900 wind tunnel runs over the course of a six-month period from September 2022 to March 2023, the experiments provide new insight into the onset and scale of flow separation which can develop on the external surfaces of nacelles under such windmilling conditions.

The experimental data enabled the influence of incoming Mach number, nacelle incidence angle, effective engine mass flow rate, surface roughness, and local boundary layer state to be established. To achieve this goal, conventional measurements such as static pressure taps, unsteady pressure transducers and surface oil-flow visualisation were used alongside optical techniques like high-speed schlieren imaging, laser Doppler velocimetry and pressure-sensitive paint in order to obtain a comprehensive picture of the flow field.

The experimental data will now be used alongside high-fidelity (well-resolved LES) simulations of the wind tunnel flow path for comparison against equivalent RANS computations to understand the capabilities and limitations of numerical approaches currently used in industry. From the lessons learned in this process, guidelines will be developed to help engine designers produce optimised nacelle geometries which do not experience the detrimental consequences of external fan cowl separation during engine windmilling.